- Overview

- Main Components to Check First

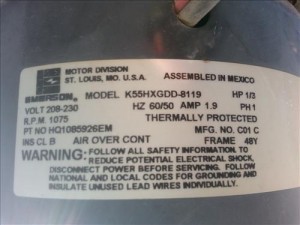

- How to Buy a New Condenser Fan Motor

- Information Needed When Buying a New Motor

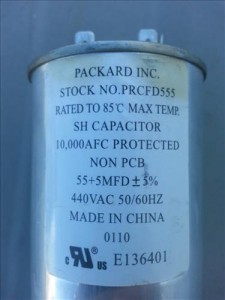

- How to Buy a New Condenser Fan Motor Capacitor

- Testing a Condenser Fan Motor Capacitor

- Replacing the Start Run Capacitor

- Replacing the Condenser Fan Motor

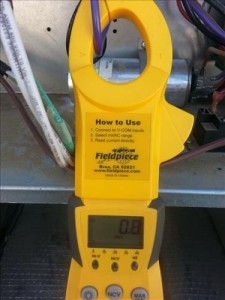

- Testing the Amperage

Overview

A bad condenser fan motor is a common problem with HVAC units; all year long, they are exposed to the weather and are required to turn on and off, constantly blowing the air away from the condenser.

When one fails, they will often freeze up after the bearings seize or draw the wrong amperage and stop working.

A condenser fan motor is responsible for pulling air out of a unit pulling it out past the condenser fins, much like a fan and radiator in a car or truck. During the summer, when it is hot, it will blow the heat away from the condenser through its fins, cooling down the refrigerant that flows inside.

When a condenser fan motor goes bad often, the HVAC unit will work initially then stop. For example, during the summer, when it is hot and a unit is turned on, it will at first blow cold air, then after a short period, it will stop and blow room temperature air.

A simple way to tell if a unit has a bad condensing fan motor is to turn the unit on and stand next to the condenser. The fan, at some point, should kick on and blow out air. The fan does not run constantly, only when needed, but if twenty minutes or more go by and the fan does not kick on, then there is most likely a problem.

When a fan motor is not spinning, a small stick can be used to reach the blades and give them a nudge which sometimes will get it running again but will soon stop. If the motor does not spin at all, the bearings are most likely are bad, and the motor will need to be replaced.

Be careful when working with a fan motor; the blades turn at a high RPM and can cause injury. Never put arms, fingers, or any body part in the path of the blades. Also, before removing a condensing fan motor, be sure the power to the HVAC unit is off. A bad motor can suddenly start working again and, if not bolted in place, will spin out of control, causing damage. The same thing can happen if a new motor is installed or the problem is fixed, and the power is on.

Always be aware that the fan may be good and the problem may be something else such as bad connections, blown fuses, contactor, or bad start run capacitor. Each of these will need to be checked to be sure the fan motor is bad. Multiple failures can happen in a unit at the same time, especially as a unit ages.

Main Components to Check First

- Breaker, Fuses, and Power

- Contactor

- Start Run Capacitor

- Operating Voltage

- Amps (Needs to match capacitor)

- The Horse Power (HP)

- Shaft Size:

- The RPM (Rotation Per Minute)

- Mounting Style

- Frame

- What direction the motor turns CCW or CW (counterclockwise or clockwise.)

- Number of Speeds

- Turn off the power to the HVAC unit and verify it is off with a meter.

- Find the side panel where the electricity is fed into the unit and remove the panel.

- Locate the Start Run Capacitor; if it is a Dual Run capacitor, there will be only one. If there are two, then only the fan motor capacitor will need to be replaced.

- Verify the MFD and voltages, then connect the new connections from the old capacitor to the new capacitor one leg at a time to be sure the connections are correct.

- Turn the power off to the HVAC unit and verify it is off with a meter.

- The fan motor will be under a circular grill and be bolted to the HVAC unit unscrew each of these bolts or nuts and set them to the side.

- Note how deep the motor sits in the HVAC unit as the new motor should sit in roughly the same spot. Pull the motor and the grill out of the HVAC unit. The wiring can be cut with wire cutters if the wiring is in place too tight.

- Note which way the fan blades sit then remove the fan motor from its shaft. The fan blades must turn correctly and should be placed to pull air out of the unit if they are placed in the wrong direction the unit will not work correctly.

(Often the end of the shaft is rusted up from the elements making the fan hard to remove from the shaft. Use sandpaper to remove the rust from the shaft making it easier to pull off.) - Place the fan on the new motor being sure the blades are in the correct position.

- The wiring will now need to be connected, be sure to keep the wires tied up away from the blade. There should be a schematic on the side of the new motor showing which color wire goes were. A schematic should also be some were around the access panel.

(There will be a lot of air pushing the wiring around so be sure to wire tie the wires into place. The wires should never be able to touch the blades.)

If it is a three-wire motor then one connection will go to the FAN on the new Start Run Capacitor. The other two wires are for power and will go to the contactor for 120 volts on each leg for a total of 240 volts.

If it is a four-wire motor then look at the schematic on the side of the motor for wire color. Two wires are for power and go to the contactor the other two wires will go to the capacitor.

(If you order a new motor, and there is four wires while the original had three wires then two wires are for power and the other two wire need to be run to a capacitor. If the original capacitor is a Dual Run Capacitor with only one leg for the FAN connection buy another capacitor to only run the fan motor. Look at the motor for the MFD and Volts. It will only need to be a single capacitor with two connections. Following the schematic on the side of the motor two wires will go to the power and the other two wires will go to the capacitor.)

Note: Sliding the wiring through to the connection points can be a pain at times. If you are very careful to check the coloring of the wires then they can be cut and wire nuts can be used to connect to the old wires. Although this is not recommended it can be done in extreme cases where the wires are all but impossible to get through the unit.

- Screw the motor back to the grill, and then bolt the grill back into place.

Checking the fuses or breakers should be the first thing to look at. If the unit has a Disconnect, be sure it is inserted properly. Opening up the side panel and checking the voltage is often the quickest way to be sure the unit is getting power. The majority of units use 240 volts; this can be verified by looking at the nameplate on the HVAC unit.

A contactor can become pitted and dirty with use and can build up a resistance or become open. When this happens, a fan motor will not be able to turn on.

The thermostat engages the contactor, which allows high voltage into a unit powering it on.

The thermostat sends 24-volts to a coil in the contactor, creating a magnetic field that pulls it closed and allows power to the unit.

If power is coming from a breaker but no power goes into a unit, the resistance can be checked with a meter from one side to the other if the resistance is high, then it should be replaced as a contactor should have very low resistance.

The Start Run Capacitor is often is combined into one capacitor called a Dual Run Capacitor with three leads but can be split between two separate capacitors.

The Start Capacitor gives a fan motor the torque it needs to start spinning then stops, while the run capacitor stays on, giving the motor extra torque when needed.

If the Start Capacitor fails, the motor will most likely not turn on. If a Run capacitor goes bad, then a motor can turn on, but the running amperage will be higher than normal, causing the motor to run hot and have a short life expectancy.

After replacing a bad condensing Fan Motor, a new Start Run Capacitor should always be installed.

A Dual Run Capacitor has three connections HERM, FAN, and COM.

HERM: connects to the Hermetically Sealed Compressor.

FAN: connects to the Condenser Fan Motor.

COM: connects to the Contactor and provides power to the Capacitor.

If the unit has two capacitors, then one is the Run Capacitor, and the other is the Start Capacitor. One will be for HERM (compressor) and one for the FAN (fan motor) connection.

Hint: It is a good idea to take pictures or write down and note wiring connections and wiring colors for future reference before starting.

How To Buy a New Condenser Fan Motor

Examine the label on the condensing fan motor for a model number.

If the exact model number can be found, then that would be all that is needed besides verifying the numbers before installation.

Often, the model number is unavailable, or it is cheaper to use a universal motor as a replacement.

The easiest way to do this is to take the motor to a local HVAC supplier and have them cross-reference it and match it to the bad motor. Be sure to also buy a new capacitor with the correct MFD and voltage.

Amazon and eBay can also be good places to buy a new Condenser Fan Motor and Capacitor.

*This site contains affiliate paid links for which a commission earned.

Example Condenser Fan Motor on Amazon

Fasco D7909 5.6-Inch Condenser Fan Motor, 1/4 HP, 208-230 Volts, 1075 RPM, 1 Speed, 1.8 Amps, Totally Enclosed, Reversible Rotation, Ball Bearing

Information Needed When Buying a New Motor

A condensing fan motor is either single-phase (1 PH) or three-phase (3 PH). The voltage for residential is usually 240 volts but be sure to check.

The voltages on the motor can sometimes be misleading such as the following.

120 volts can also be referred to as 110V or 115V

208 volts can also be referred to as 200V

230 volts can also be referred to as 220V or 240V

460 volts can also be referred to as 440V or 480V

The fan blade needs to be mounted on the shaft at the same depth as it originally was set at. Basically, the fan is pushed onto the shaft until it reaches the same location as it was before pulled. Be sure to check how far the fan blade sits inside the unit before pulling the motor.

Usually, the motor is fastened to a curricular grate that it is bolted to.

Most HVAC motors are a 48 Frame, with a body diameter of approximately 5-5/8″.

Most universal-style motors have an option to reverse the direction of rotation.

Motors will often have multiple speeds. It may be necessary to adjust airflow for the specific installation or for different operating modes.

How To Buy a New Condenser Fan Motor Capacitor

A new Fan Capacitor should always be installed with a new motor. A capacitor can be bought at an HVAC supply company or online with Amazon or eBay.

Here are two common capacitors, the one on the left is a Dual Run Round Capacitor, while the one on the right is a Run Oval capacitor.

The Dual Run Capacitor is nothing more than two capacitors in the same housing, while the Run oval is a single capacitor, and an HVAC system will usually have two.

Capacitors are measured by the Microfarad, sometimes shown by the letters uf and voltage.

This picture shows a Dual Run Capacitor and reads 55+5 MFD (uf) 440 VAC.

The larger number 55 MFD is for the compressor, while the lower number 5 MFD (uf) is for the fan motor. The lower number is always going to be for the fan motor. Then the voltage 440 Volts AC.

In any HVAC unit the capacitor must match the motor.

The voltage can go higher if necessary but never lower while the MFD (uf) should always be the same.

(The + -5 after the MFD is how much the capacitor tolerance is rated to go up or down.)

To order a replacement for this capacitor it would be 55+5 MFD (uf) and 440 volts AC Dual Run Capacitor.

Example Dual Run Round Capacitor on Amazon

MAXRUN 55+5 MFD uf 370 or 440 Volt VAC Round Dual Run Capacitor for Air Conditioner or Heat Pump Condenser

Testing a Condenser Fan Motor Capacitor

Testing an HVAC capacitor is done with an HVAC multi meter, the multi meter must be cable of reading the range that an HVAC capacitor can have. Many small electronic meters do not have this range. Here I am using the Fieldpeice HS36 multi meter with an Amp clamp

This test is being done on a Dual Run Capacitor 55+5 MFD (uf). The multi meter is on Farads and the leads are on C and FAN (positive and negative do not matter). The lower number is for the fan motor which is rated at 5 MFD (uf), and it reads 5.3 MFD (uf) so it is good. The leads C to Herm can be read also which would be for the compressor.

Here is a single Run Oval Capacitor rated at 5 MFD (uf) and 370 volts AC

To test a Run Oval Capacitor simply touch the two leads. This one reads 4.5 MFD (uf) and is rated at 5 MFD (uf), so it is bad and needs replacing.

Replacing the Start Run Capacitor

If you have two capacitors, then one is for the compressor, and one is for the fan motor.

A new fan capacitor should always be installed when a new motor is installed. It is always a good idea to take a picture or write down wire coloring and connections.

Be sure the power is off on the HVAC unit by turning off the breakers, or pulling the disconnect. Do not turn the power back on until the motor is back in its place and bolted in.

It is a good idea to take pictures of the wiring connections and motor to refer back to if necessary.

Replacing the Condenser Fan Motor

Testing the Amperage

An amperage test should be done to be sure everything has been done correctly. Here is an HS36 multi meter with an Amp clamp showing the amperage from the fan motor. This Fan motor was rated at 1.6 amps, anything under that would be good. Here it is showing 0.8 amps well below the 1.6 amp rating.

If this is not an option then close up the unit and power it on. Neither the fan motor or the capacitor should get too hot. There is a temperature rating on the nameplate of each motor if it goes above this it can shut off and possibly damage the motor.

All information written here is for HVAC students, technicians, or properly trained personal. Do not attempt any of these procedures without the proper training. Replacing a condenser fan motor can be dangerous do not attempt this without proper electrical training, construction training and safety practices.

Replaced fan motor : heck of a time getting it back in position. Fan ran for few minutes, kicked off, back on then off again. Motor had felt HOT to touch when we were working on it third time. Room temp air out of floor vents.Compressor runs but fan won’t stay on. Turned unit off. What can we do to fix it ??

When you replaced a condenser fan motor it is very important that there is more than just making the frame be the same size to fit like the old one. You must make sure the specs are the same as the old one. That means the RPMs, & the HP must be the same and the rating of the start capacitor the same as the old one. If a dual capacitor is to be used so that one capacitor is for both the fan and the condenser make sure the voltage rating for the condenser run capacitor is not lowered then the one that was on the old capacitor. Higher is Ok. an example is if it is 30 but it calls for 45v ( read your model unit on the condenser and take that or at least call that number to the supplier of the new motor so that he can cross-reference it as to being listed as an OEM replacement motor for the model number on the condenser . . .

Good article and nice clear pictures.

1) How come the blades are so freaking expensive. Even two blade are over $50 for a few pennies of sheet metal, a hub and some rivets?

2) Can I use a CW or CCW blade interchangeably?

i hooked up a various speed motor to trane xe1000. Two to 120 white wire power and black wire hi speed and one brown wire to oe 3 leg capacitor. Everything worked fine. Two hours in the compressor shut off but fan will still run. Every time it starts up the compressor comes on for a couple seconds then turns off. Fan stays on until I turn off thermostat. Should I be running a second capacitor for just fan and run the original hot jumper wire for the compressor 3 leg capacitor?

Info very useful. Will try to get our unit working.

Excellent information. Very helpful replacing my 3 wire motor with a 4 wire motor. The information on how to wire in the additional capacitor saved me a service call. !

My motor needs to be replaced. It shows an arrow pointing to the left. Is that counter clockwise? Thanks

Yes it would be CCW or Counter-Clockwise.

Changing a condenser fan motor is always a heck without a proper guidance. This will help a lot to make the replacement very easy.

Got a new fan motor which reads 3/370 5/370. My capacitor reads 45+5 plus or minus 6% Are they compatible?

Changed fan motor and capacitor when fan kicks on makes humming noise blowing hot air then few seconds later stops and reverses itself and starts blowing cool what could cause and is it normal for the fan to turn one way then stop and reverses itself.

My Goodman heat pump fan motor and capacitor has been replaced and now it won’t run at all. Before it just hummed. Help

Great article. Very useful information. I have a universal replacement fan motor that I am trying to install currently. But the wires that came with the fan aren’t long enough to run to the units panel. Whats the best way to extend these? What kind of wire is needed? Or does it even matter? Thank you.

Air condition unit went out I called serviceman he came out said it was the motor fan he replace the motor fan with another one but the one he put in it’s not the same as the one that was in there. this motor fan blade are shorter and the fan sit deeper in the case will this cause a problem with the air condition unit will it cool the way it supposed to? he said he is concerned about the

Comment on “If the original capacitor is a Dual Run Capacitor with only one leg for the FAN connection buy another capacitor to only run the fan motor” :

You actually don’t need to buy another capacitor. Just Connect the Brown capacitor wire to the FAN connector of the dual cap and the Brown & White wire to the C terminal of the dual cap.

Really great article. Explained a bunch of items that I hadn’t found elsewhere (or were inaccurate there).

I replaced the dual capacitor and a run capacitor that was attached to it and now the fan is working again. You explanation of 4 vs 3 wire fans (fan was replaced by a technician a few years ago) explains why the dual run capacitor sprouted a smaller oval two-terminal run capacitor by it’s side.

The explanation of the contactor also helped clarify one of the items I was wondering about.

I’m still trying to find the start capacitor P281-1356 in the same unit. A Carrier model heat pump 38YCB024 310. I don’t see it in the access panel on the side of the outside unit where the dual capacitor is. Where can it be? The compressor is running, but with the age and the others already breaking I’m looking to find it.

Having hard time w/our outside unit. Replaced fan motor. Wouldn’t keep running. Will try the “stick” to get fan running.

If you need a stick to have it run, then you need to replace the capacitor for the fan. One of its job is to start that fan moving. Make sure to buy a capacitor that is for that motor. I just replaced my motor, added a capacitor for the motor, replaced the existing capacitor as it was going bad and added a hard start kit to help extend the life of compressor. Might be overkill, but cheaper than replacing the whole thing, which is what an hvac tech told me to do. All total was $100 for the parts I installed

Hi, I had my fan replaced on my 4 ton outside unit. Now there is more vibration and a louder noise. The grill vibrates so much more that I had to put foam all around the grill. He put in a 1/3 HP motor with 1075 RPM. Does that sound right for a 4 ton unit. Would going down to 1/4 HP or less RPM make a difference and still function on a 4 ton.

When I brought it up to the repairman, he said that I now had the right size motor and the vibration an dmore sound is normal. Just the way he said it, tellsme, that may be the only fan he had with him.

Please advise

thanks

Steve

I’m a home brewer and got a unit from eBay that came from a vending machine – it cools water via a heat exchange. During testing it cooled 5 litres of water 10c in 20 mins. (29c to 19c) (1kcal / litre / 1c = 50kcal = 198.3 btu’s removed over 20 mins).

I’d like to use it to manage fermentation temp, as commercial units for this purpose cost around 1k and are far bigger than I need. I calc I need a cooling capacity of 12btu/hour for my fermenter (using an online brewing chiller sizing calculation), and the chiller has ample capacity.

Anyhow, the fan over the condenser is loud. It doesn’t sound like the bearings are gone, just a loud fan, high rpm and wind noise. I don’t think noise limitation was a design factor as the unit is from a commercial vending machine…

I’d like to swap the fan unit out with something quieter – although am wary of making a potential fire hazard / ruining the compressor. The fan is an axial fan, the same size as a pc psu cooling fan and am thinking of getting a “silent” pc fan and retrofitting it.

I guess is comes down to airflow – if the airflow of the new fan is not adequate I think run the risk of the compressor over heating and seizing up. I’m thinking that, as my cooling needs are far less than the unit can manage, I’ll probably end up with the unit running longer to cool the same volume of liquid. I think the unit will only run for ten mins / hour, and max temp output during fermentation is over 72 hours, then tapers off.

I appreciate your thoughts and advise about this, unsure who to ask