If your furnace needs a new control board, the average cost for an HVAC technician to install it is $400-$700.

If you are a DIY type of person, furnace control boards can be bought online for $50-$250, depending on the furnace.

Can I Replace My Own Furnace Circuit Board?

Doing it yourself is very tempting so let’s look at a few things needed to do it.

First, be sure the board is bad. This often requires an HVAC tech to look at the furnace since many variables exist.

The control board should have a LED that flashes error codes. The codes often are listed on the panel door or somewhere in the unit.

If you have already gotten this diagnosis from an HVAC company, more than likely, this is the problem.

Buying the correct board online is the next step.

I personally usually use Amazon, but this is simply a personal choice as they have a large selection; eBay also has a good selection.

If you order a new control board, be sure to match the part number from the old board or the name and model of the furnace.

Example Furnace Control Board On Amazon.

ICM – ICM2805A – Furnace Control Board, 120/240 Input Voltage, for Use with Commercial HVAC Equipment, Residential

Every furnace will be slightly different, and the manufacturer’s directions should always be followed.

Steps To Replacing Furnace Control Board

- Unplug the furnace.

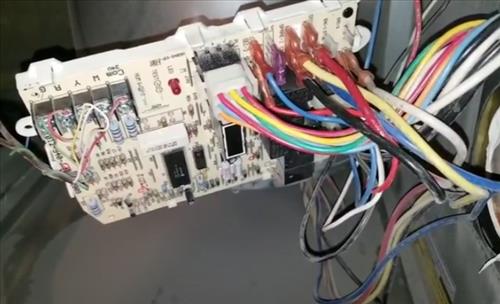

- Take a picture with your phone of the wiring and possibly a video. Simply be sure you have a reference to fall back to for what wires went were.

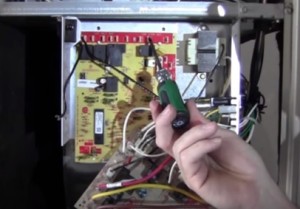

- Before handling the new board, ground your hand on a metal surface since static electricity can damage control boards.

- Remove the screws holding it in place. Try to leave the wires attached if possible; if this is not possible, transfer the wires one at a time to the new board.

- Insert the new board and screw it into place.

- Attach the wires to their correct location.

- Verify the wiring is correct from the picture that was taken.

- Plug the furnace back in and test it.

What Causes a Furnace Circuit Board Failure?

Circuit boards usually fail because of bad components or a surge in electrical.

Components such as resistors and capacitors can go bad, often caused by low-cost electrical parts.

An electrical surge such as an electrical store can also damage a circuit board and is a common cause of failure.

Summary

The cost for an HVAC tech to replace a furnace control board can be high but is necessary if you do not feel comfortable doing it yourself.

It does not take a lot of skill to replace a furnace control board, but if you do, be sure to watch a few videos like those listed below.

Also, be sure to get the correct replacement board using the part number.

Have yo had a replacement cost quote on a furnace motherboard control board? let us know in the comments below.

“It doesn’t take a lot of skill to replace a control board”!? Lets say you need to fight an insurance company to receive your proper dues. Are you going to fight them? NO, YOU ARE CALLING A LAWYER! Why? He or she has SKILL and KNOWLEDGE OF THE LAWS! If you have gone to school, obtaining expensive tools, working long hours, additional training due to new efficiency standards, troubleshooting accurately and properly, taking the proper readings as per manufacturers specifications, making sure there are no other reasons for said breakdown, and making sure the system is safe to use afterward, you would not have made that statement. DO NOT FEED THAT NONSENSE TO THE PUBLIC! This is the reason we trained and certified service technicians across the industry have a difficult time with clients.

I was responding to your clap-trap. Yes, there is a “reason [you] ‘trained and certified service technicians (I guess you ARE talking for your whole industry) have a difficult time with clients”, and I’m so proud of your education and professional test taking skills. ho-hum.

Do you respect your DIY clients? Do you discuss their issues, let them hear some of the ‘bone head’ things you’ve seen DIY or terribly underqualified competitors do in other homes? Lord, I’ve discussed the benefits of an ALL PROTEIN DIET and juice fasting and meditation and an evening walk with patients. Do you know each of those things are useful in the right situation? And harmful in other situations? Put a kidney failure relative on a high protein diet to help them heal – you will kill them.

So right, lump all HVAC techs in the same ivory towered service profession and all homeowners who are looking to save a buck in the nincompoop category. I hope you are one of those HVAC guys who in the first flurries of winter when a new father calls for service – and it is late – but you show up to find a neighbor with the key who says “He had to take his wife to the hospital, they are having their first baby”, and even though you are uncertain about walking into a home unsupervised, you go look at the system, repair the ignitor or the malfunctioning sensor, clean the system, change the filter, and leave a note – “Congratulations on your new addition, I hope all of you are comfy this winter. Call if this system needs anything – today’s charge – PAY IT FORWARD. I do this for people who strengthen our community and new families ARE our community”.

Now that guy is a HVAC tech I’d invite to my house for a beer!

Some repairs require advanced knowledge, some are simple parts tradeouts. I had a burnt out heating element in my oven. Two screws. Check with an ohmmeter. $15 for the element on Amazon. Now, a repair person would charge minimum $100 labor and would mark the part up to $50.so $200 vs. $15 and an hour of my time.

Would I mess with gas connections? No. Diagnose complex wiring problems? No. But don’t tell me you need to be an expert to solve simple parts replacement.

I just bought a used Circuit Board for my Bryant Heat Pump. What a godsend.

The HVAC guys that tried to troubleshoot the problem, could’t figure it out in two house calls.

Around $300 for two visits. Communication Error code.

I chased out the wiring continuity. No faults.

It has to be the board.

So I look up the Replacement Board for my model and it’s $500.

I ordered a used one for $70. Installed it in about 20 minutes and my heat pump works perfectly again.

Everyone should know about this option.

If you are the least bit handy, this kind of fix is incredible.

Thank you for discussing this amazing option.

Here’s another experience .

I just replaced the controller board on a furnace at one of my rentals.

Another three visits from HVAC specialists, two who didn’t even check the board, just replaced the thermostat and cleaned the flame sensor. $400 altogether.

After being told by the last tech that the board replacement would again be $500 and that they would replace the furnace for $2000, I bought a replacement board and again, installed it in 20 minutes.

Worked perfectly once again.

Not all HVAC techs are created the same. Just like all lawyer.

There is an inherent conflict of interest when it comes to servicing a client.

Unfortunately, there is a lot of motivation toward getting a client to spend their money.

Even your handyman could replace a furnace board.

I’d look inside to see if the bottom of the z coil is plugged with fuzz. I just took care of a client with that issue recently. It’ll definitely give you the same scenario that you described. If your coil is icing up it’s one of (or combo of) 2 things: bad air flow and/or low freon. With yours having a txv instead of an orifice my money is on low freon. But if your system has crud in the lines it may be another stuck txv. Or your air flow is bad because of plugged fins. I wish I could come look at it for you! I hear all you’re saying about bad techs! I am a somewhat newbie but have a good conscientious trainer. He always has told me “Don’t be a parts changer. Track the symptoms andfind why it’s doing whatever it’s doing.” I wish you the best.

My AC is icing up, my heat exchanger is ‘getting too hot’ so our HVAC service tech ‘sped up’ the heater fan (ie, put the cooling [black] wire from the squirrel cage onto the heat tab, put the purple or heater wire on the cool tab), and as then the heat exchanger sensors went back to ‘high normal’ temps. I am concerned by the level of training our licensed & bonded HVAC techs have here – they can discuss superheat and low pressure and discuss possible issues (my pop was the DIY kind of guy who taught me how to repair gas furnaces, gas stoves, gas water heaters, airconditioners, and even automatic transmissions when I was a boy, years before medical school and years before my brother (the judge) became a lawyer. Why do I seem to ask the right questions and get the wrong answers from our techs?

I don’t know why my “A-Frame” (which is really a Z-coil because of the size of the unit) is icing up. Without my pop here to look at it all (and use trial and error to hunt down the problem), I’m left with 3 fixes. Check the charge myself after buying the necessary gauges; Check the charge (see previous) and inject some drying agent-leak sealer/whatever it is called (and look at the system under a woods lamp – ultraviolet light); or upgrade the PCM motor to a larger PCM or a higher air-flow ECM motor and control board. There is also the option to call another HVAC company to analyze what my current company has done – or can’t do.

As a retired physician with fixed income beginning to pale with college expenses and family obligations, I can let the house heat up a little during this summer – but I’d like to figure out my problem. Don’t get me wrong – although I have rebuilt engines, transmissions, and even rebuilt an old pick-up truck from a rusted hulk to an ugly but very serviceable and safe truck, I know when to let a professional work on things. I still like to know what is going on behind the screen as it were. If I can solve my AC freezing up problem, I will. Why my airflow in my ducts seems to have dropped (beyond the swapping of the PSC wiring on the control board) is beyond me, the ducts are the same as they were for the 8 years the AC was working fine…until 2018 when we had to have the Z-coil replaced with a new txv valve, and then had to have a new valve brazed into place this spring when the icing continued….now it ices every 3 or 4 days instead of every 3-4 hours…..

It doesn’t take a rocket scientist to analyze these issues – anymore than it takes a electrician to figure out all the lights out on a street may indicate the problem isn’t in my own home’s breaker box.

So to the “Trained HVAC technicians” who are so proud of the certification and training and don’t do the exact thing we physicians get dinged for – speaking WITH our customers and making sure they understand what we are saying….you are a dime a dozen and as helpful as just picking a lawyer out of the phone book because we knew someone with that name in High School. I’ve had 3 HVAC guys I’ve worked with (they worked for me, on my house in another state) whom I respect and wish were here to look at my system. If you guys have problems with your clientele – it may be because your clientele are terribly entitled (I know many of my patients were) or you are rather aloof and assume the ‘little lady’ or old white collar guy just can’t understand the issues with a metal box that pumps out heat or strips heat away in a simple forced air system. I’m that old guy, and I don’t like a condescending physician (now that I’m on the receiving end and not just chastising my residents for that behavior – I hate it) anymore than I like a newly minted HVAC tech giving it the old college (trade school?) try and nothing improves.

You can get a physician that won’t click, most especially if you don’t try to meet them halfway, you can get a lawyer that just takes you for your retainer (they are all actor – wannabees anyway – ever sit in a courtroom?), and you can get service personnel who are leveraging their knowledge for their financial benefit. Not everyone of them, but there are a fair number of each in all professions.

Good to vent, wish my HVAC system was ‘venting’ more powerfully, and don’t know why the airflow has dropped. I’ll have to crunch some numbers (I have an old set of guidelines that seem to be jibberish on how much of an HVAC system and how much airflow per square footage plus more for windows and less for well insulated areas, etc….if I find it I’ll start taking measurements this week. I know it is here somewhere). But this looks like a good forum and I do think the HVAC techs who complain about DIY are off base. You do have a job – and you should be able to fix our screw-ups – after all, you eat wrong, you have too much stress, you come to primary care physicians and we are supposed to give you a course of therapy (behavior/diet modification, medication, and reassurance) – you guys are supposed to do the same for us when we screw our systems up (HVAC systems).

Thanks

I would start with the basic stuff like check the filter and the blower wheel for build-up of dust and hair. To see if that will help with air flow and check the duct for build up also and the return for build up. If that does fix the problem then I would check the static pressure at the return and the plenum and make that up with the chart on the inside of the furnace or on the door panel.

Probably the ductwork is bad. . . Doesn’t allow the right cfm to pass

You changed the evap coil. An iced up coil will cause a low air flow condition. A quick look at the coil to confirm it is clean would be a good idea. I wonder if it was an exact match. Not seeing what your original coil looked like it is possible it may have just been dirty. I don’t see any reason to replace the coil unless the coil leaks refrigerant. Maybe if the fins were damaged somehow or too plugged up with dirt to clean it thoroughly. There are so many things that could cause your problem. One of the first things I would do is to check to see if the indoor blower motor is turning in the right direction. Low refrigerant charge or overcharging can cause the unit to ice up. An iced up coil can cause low air flow.

I’m not sure what a pcm motor is but if it is a psc motor you can check the amp draw to see if it’s not overamping.Have the capacitor checked. You can also buy a capacitor real cheap on amazon. Just make sure it matches the motor requirements. It is normally listed on the motor. If it is an ECM motor you can check the amp draw too. Getting a bigger motor will not correct your problem.

Our electricity provider lends out tools to the homeowners. Maybe yours does too. A flow hood to check cfm at all your vents will give you an idea if that is your problem. Rule of thumb is 400 CFM/500 square feet . Average static pressure across a unit is normaly .5 inches water column. You will have to look up the specs to get the right requirements.

Ask your buddies what they think. Finding a good mechanic would help too. He may have to spend some time working on your unit to figure it out. Don’t hover over him while he’s working. Give him a chance to concentrate on what is going on with your unit. Good luck.

How does the board cost and the cost to have it replaced. My furnace is 28 years old and its a ruud

RHEEM carries parts for the Ruud unit’s

Our control board actually burned up. HVAC guys think we should replace the whole furnace because we don’t know what caused the fire. Could the fire have been just the control board itself?

Thanks I have a guideline to follow now. I was in the blind-cost-steps. I hired Hvac for repairs today.