A furnace blower motor can be replaced by a handy DIY homeowner, which can save money.

Of course, if in-doubt, be sure to call a professional HVAC technician.

A new motor and capacitor will need to be bought to replace the old unit.

Most hardware stores will not carry a furnace motor, but a new unit can be bought easily online on Amazon or eBay.

Read Here For How To Buy a New Furnace Blower Motor and Capacitor

How To Replace a Furnace Blower Motor and Capacitor

- Turn the power off to the furnace.

- Locate the furnace blower motor.

- Locate the Furnace Capacitor.

- Take pictures of the blower motor and capacitor.

- Remove the blower motor assembly.

- Remove the fan blades.

- Remove blower motor bracket.

- Bolt the fan blades back into place.

- Install the new capacitor.

- Double check the assembly.

- Install the assembly back into the furnace.

- Tighten the bolt holding the assembly in place.

- Reattach the wiring.

- Test the blower motor.

Be sure to turn off the power to the furnace or unplug it before any work is done to a motor or any components.

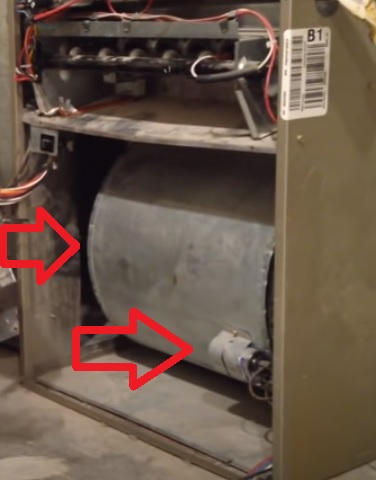

The first step is to locate the motor, which is the only large motor in the furnace.

Here is a furnace motor assembly and capacitor bolted onto the assembly.

Look for a Start or RUN Capacitor since this will also have to be changed (if the furnace has one). A bad or failing capacitor can damage a new motor, so it must be changed any time a new motor is installed.

Some furnaces don’t have a RUN or Start capacitor, which can vary between units.

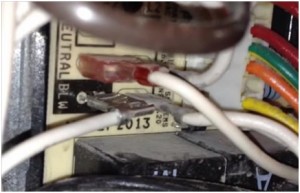

Before anything is removed or any work done, take pictures and write down all the wiring and connections.

Take good pictures or a video to refer back to later if needed. If something is wired wrong, the motor may burn up, or at the very least, not work. Having pictures to look back at can be invaluable when reconnecting everything.

Once you have good pictures of the wiring, the wires can be unplugged and removed.

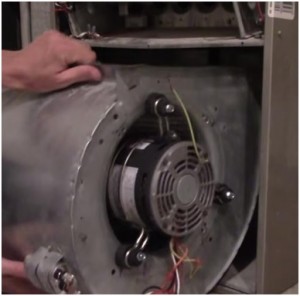

The motor will be inside of a sheet metal assembly, making it necessary to remove the entire assembly.

Screws holding it in are usually located in the front with a notch in the back it can slide out of.

Once the entire assembly is taken out the bolts holding the fan blades in place need to be removed.

One bolt will hold onto the shaft and needs to be loosened to slide off.

To remove it, loosen it up so that the shaft can pull out from the fan blades. It is a good idea to oil up the end of the shaft so it pulls out easier as some can be a pain. If there is any rust or build-up on the shaft, use sandpaper to remove it and then oil it. Otherwise, pulling a motor from the fan blades can be very hard sometimes.

Next, the bolts holding the back of the blower motor should be removed, and the motor pulled from the fan blades.

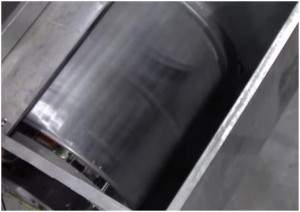

On a side note, it is a good idea to clean the fan blades when the assembly is out. Debris build-up on fan blades makes them work less efficiently; cleaning them is always a good idea. If the fan blades are very dirty, take them to a car wash and, after spraying them with de-greaser, power wash them.

The motor will have a ring that goes around it and bolts to the housing; this should be taken off the old motor and put on the new one. In some cases, it can be damaged if it has been a new one can be bought.

Once the ring has been placed on the new motor, the shaft can be slid back onto the fan blades and bolted into place.

When bolting the fan blades in, they will need to be centered, so the blades spin freely in the housing.

Before tightening the bolt on the shaft, be sure it is centered correctly since there is a flat spot on the shaft that is where the bolt screws into holding it in place.

Before installing the assembly back into the furnace, be sure the fan blades spin without hitting the housing.

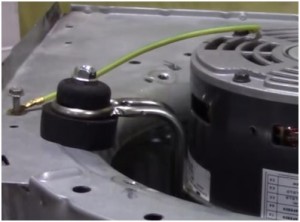

Remember to connect the ground wire to the case.

Install the new capacitor and connect the correct wires from the motor.

Double-check everything is connected, the fan blades are spinning correctly, and it will be time to reinstall the assembly back into the furnace.

Installing it will simply be the reverse of taking it out. The hardest part is often getting it to slide in correctly into the metal tabs.

After getting it back into place tighten it in with the holding screws.

After getting the assembly back in, double-check the fan blades again for proper spinning, you don’t want to damage anything when power is applied, and they spin fast.

After the assembly is back in place, the wiring can be reconnected. This is where the picture taken earlier comes into play.

If there is a wiring problem, look at the schematic for the furnace and examine the wiring.

Turn the power back on. It is always a good idea to double check everything before turning the power back on.

Once the power is back on, and the thermostat is set, the furnace should kick on and the blower motor spinning.