Through the ages people have used some means of cooling foods. First, they cooled foods by lowering them into wells or storing them in caves. Following that, natural ice was used. This ice was cut in the winter and stored underground for use in warm months.

The Egyptians also used another means of cooling water. They found that they could keep foods cool by storing them in clay containers. This method was quite successful because the water slowly seeped through the porous walls and dried on the outside wall. This drying action, known as evaporation, caused the jar and its contents to cool. This same principle of evaporation of a liquid is the basis of modern mechanical refrigeration.

This method is still used today in parts of the world.

Mold, yeast, and bacteria require warmth in order to grow and multiply.

Their growth and multiplication can, therefore, be slowed by cooling the food to a sufficiently low temperature. This reduction in temperature may be done by modern refrigeration equipment. Refrigeration is actually the most valuable method of protecting foods against spoilage. It is the only method that preserves food in its original state and does not appreciably affect its flavor, appearance, or nutritive value. Before the existence of refrigeration, most food had to be eaten shortly after being obtained. Therefore, people who lived in one area would have difficulty enjoying foods that were plentiful in another area.

Also, foods that were plentiful in one season of the year could not be enjoyed in another season. It was discovered many years ago that several benefits are derived from cooling food. All food, except frozen foods that are properly prepared and protected, should be kept below 50°F (10°C)* and above 32°F (0°C) to prevent spoilage by either microbic growth or by freezing. The zone between 50°F (10°C) and 32°F (°C) is recognized as the food safety zone and is commonly referred to as safety zone refrigeration.

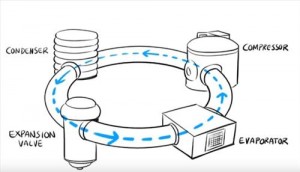

The icebox came into existence when natural ice became available. People who lived in warm, dry sections of the country, however, could not afford natural ice because transportation was expensive. It was also dis-covered that some of the natural ice was contaminated and could not be used safely. More than 150 years ago, an English scientist changed ammonia gas to a liquid by applying pressure and lowering the temperature. As the pressure was released, the ammonia liquid boiled off rapidly and changed back to a gas. As the liquid boiled off, heat was absorbed from the surroundings.

This discovery proved to be of tremendous importance in the development of modern refrigeration equipment. The first commercial ice machine was introduced in 1825. The ice produced by the machine was cleaner and purer than natural ice. The ice also could be produced regardless of weather conditions. By the early 1900s industrial refrigeration using the mechanical cycle had been developed, and meat packers, butcher shops, breweries, and most of the other industries were beginning to make use of the mechanical refrigeration units that were available. When the electric industry began to grow and when homes were beginning to be wired for its use, household refrigerators became more popular and began replacing the common window and standing iceboxes.

These types of iceboxes required a block of ice every day to function properly. The new refrigerator did not have this requirement. The interest and demand for household refrigerators was aided by the design and development of fractional horsepower motors, which were used to operate the compressors used in these refrigerators. These units began being produced in large numbers in the early 1920s and have become a necessity for all rather than a luxury for the rich. With the development of the modern apartment house and the increased demand for more and more cooling, the need for refrigeration equipment became more apparent. Home food preservation today is not the only use of these systems, but commercial food preservation has become one of the most important present-day applications of refrigeration units. The commercial preservation and transportation of food is so common today that it would be difficult to imagine living without this industry.

Approximately three-fourths of the food used in homes today is produced, packaged, shipped, stored, and preserved through the use of refrigeration equipment. There are literally millions of tons of food stored in ware-houses that are cooled by a refrigeration unit. Also, there are millions of tons more that are stored in frozen-food warehouses, in individual locker plants, and in packaging and processing plants. The commonplace storage and transportation of all types of perishable products would be absolutely impossible without the use of different types of refrigeration and air conditioning equipment. Due to the refrigeration process, we are not limited to the enjoyment of fruits and vegetables and other produce that are locally grown at any given time of the year; we can also have foods grown and processed in other parts of the country on a year-round basis.

The evolution of refrigeration has improved the economy of almost all areas because it is a means of preserving products while being shipped to customers. It has played a large role in the development of agricultural regions because of the greater demand for products. The dairy and livestock-producing areas have also en-joyed the growth brought about by the use of refrigeration.

We can define refrigeration as a process of removing heat from an enclosed space or material and maintaining that space or material at a temperature lower than its surroundings. As heat is removed, a space or material becomes colder. The more heat is removed, the colder the object becomes. Cold, therefore, is a relative term signifying a condition of lower temperature or less heat.