There are two types of window air conditioner room units, both cooling and cooling and heating types.

These are the window installation and the wall installation.

Window insulation may be considered temporary because the unit may be removed and the window put back to its original use.

The wall installation is permanent because a hole is cut in the wall and must be patched if the unit is removed.

When a unit becomes old and must be changed for a new one, a window unit will be easier to replace.

A new unit may not be available to fit the hole in the wall.

Window installations are either for the double-hung window or the casement window unit.

The double hung window is the most popular.

Window units may be installed in other types of windows, such as a picture window location or jalousie windows, but these require more carpentry skills.

A special unit is manufactured for casement window installations.

Every installation should follow some general guidelines. The inside part of the installation requires that the proper electrical outlet be located within the length of the cord furnished with the unit.

Extension cords are not recommended by manufacturers.

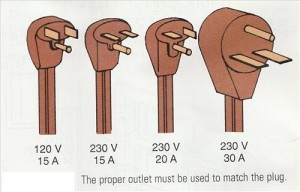

A proper electrical outlet must match the plug that comes with the cord. Window units can be either 115 or 240 V units and should be on a circuit by themselves.

When 115-V operation is chosen, it is usually to prevent having to install an electrical circuit.

Although this choice is often made without investigating the existing circuit as it may have already have a load on it.

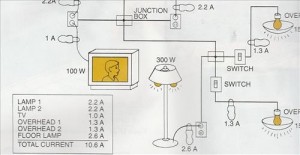

For example, a 115-V electrical outlet may be part of the lighting circuit and have a television and several lamps on the same circuit.

The addition of a window air conditioner of any size may overload the circuit.

An investigation of an electrical circuit to see what extra capacities are available is necessary. This may be accomplished by turning on all the lights in the room nearest outlet intended for use.

The adjacent room lights may also be turned on, and the breakers that controlled the outlet may be turned off.

The current load of the lights may be totaled by adding them mathematically or use an amp meter on the wire to the circuit.

The circuit is already using 10 A and is a 15 A circuit a window unit consuming 6 A will overload the circuit.

A typical 5000 BTU unit will pull about 7 A, when 115 V is used.

An inexperienced homeowner who buys the unit at the store and installs it may be in trouble if the unit will run on a slightly overloaded circuit.

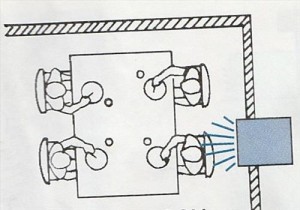

Other considerations on the inside of the room are the best window to use and the air direction.

A window that will give the best total room circulation may not be the best choice because it may be next to the easy chair, the bed in a bedroom, or behind the dining room table.

Some people purchase a large window unit for several rooms.

The unit must be able to recirculated air to the adjacent rooms, or the thermostat was shut off the unit and cool only one room.

A floor fan can be used to move the air from the room with the unit.

Through-the-wall units in motels usually seem to be located on outside wall under the window and where the chairs and table are located.

This is the best practical place for the unit, but not necessary the best for the occupants. However, there may be no other place in a small room other than outside wall.

A unit located where air will circulate, for example behind the drapes, will be a problem in insulation.

Air will continually recirculate to the return air grill and be cold enough to satisfy the thermostat shutting off the unit.

Some small units have no thermostat only an on-off switch.

These may freeze the evaporator solid ice.

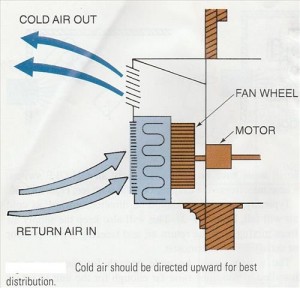

Typically the airflow should be directed upwards, as cold air will fall.

This also keep the supply air for mixing with the return air and freezing evaporator satisfying thermostat.

The window must be wide enough for the unit to be installed in and must raise far enough for the unit to set on the window ledge.

Smaller window units are of a size that when they are placed on the window ledge, they will almost balance. The center of gravity for the unit is near the center of the unit.

In larger units compressor is located more to the rear causing the unit to have a tendency to fall out of the window unless half of the unit is extended into the room. This of course is not desirable.

Most manufactures provide a brace kit to support the back of the unit. The bracket takes the pressure off the upper part of the window and places the load on the bracket

When the unit is place in the window it never completely fills the window.

A kit is provided with each new unit to aid in the refilling the hole. This kit may be telescoping side panels or panels to match the unit color that may be cut to fit.

When the window is partially raised to accommodate the window unit, the space between the movable window parts must be insulated.

Usually a foam strip is furnished for this purpose.

Directions are included with each unit. However in some instances the unit may be removed, braces and window kit misplaced, and when reinstalled without braces and a proper window kit, a poor insulation may result.

Some awkward installations can be seen because of this units that are installed and not properly brace will vibrate, sometimes called window shakers.

A unit properly braced will be typically be slanted slightly to the rear for proper condensation drainage. When the weight is supported by the back, it relives the pressure on the window and reduces the vibration.

Most units evaporate the condensate, but some allow it to drain out the back. This condensation should drain to a proper location.

Some are installed so that the condensate drips on the sidewalk is not a good as algae may form and the sidewalk become slick.

The unit must be installed in such a manner that air can recirculate across the condenser. It must be allowed to escape the vicinity and not heat the surroundings.

Window units have been located with the condenser and a spare room, such as a business. This is poor practice because the units heat the air and high operating conditions will occur.

Re-circulation will cause high head pressure and high operating costs.

Obstructions must not be located close to the air discharge.

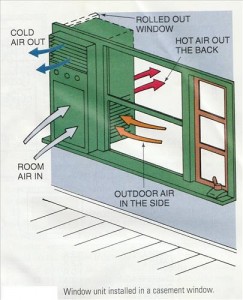

Casement window installations require special unit unit is narrow and tall, to fit the roll-out portion of the casement window.

If the window is double, a regular window unit may be installed by cutting out part of the fixed portion of the window, This requires some skill.

When the type of insulation is performed, all stresses must be on the windowsill. If the unit is removed, another repair job must be performed.

Through the wall units typically protrude into the room, with only a slight amount with the bulk of the unit on the outside.

When these units are installed in a motel outdoor portion protrudes into the walkway slightly. If the condensate is not fully evaporated, it will run across the walkway and cause hazards.

Through the wall units may be installed when the building is under construction.

This is accomplished by installing walls sleeves and covering openings until the unit is set in place.

The wiring is run to the vicinity of the unit, and the unit is connected when installed.

Is important that the correct size hole be cut, the wall sleeve should be purchased from the manufacturer in advance to ensure this.

Controls for room units, cooling

Room units for cooling and heating are typically plug-in appliances furnish with a power cord.

All controls should be furnished with the unit.

There is no wall-mounted remote thermostat as in central air conditioning. The room thermostat sensor is located in the unit return air stream.

A typical room may have a selector switch to control the fan speed and provide power to the compressor circuit.

The selector switch may be considered a power distribution center.

The power cord will usually be wire straight to the selector switch for convenience. Therefore it may contain a hot neutral and a ground wire for 115 V unit.

A 230-V unit will have two hot wires and a ground. The neutral wire for the hundred 115 V unit is routed straight to the power consuming devices.

The other hot wires connected directly to the other side of the power consuming devices.

Many combination of selector switches will allow the owner to select fan speed, high and low cool, exhaust, and fresh air.

High and low cool is accomplished with fan speed.

Because the unit has only one fan motor, a reduction in fan speed slows both indoor and outdoor fan.

This reduces the capacity noise level unit. A slight power saving is also achieved.

The exhaust and fresh air control is a lever that positions a dampener to bring in outdoor air or exhaust indoor air.

The selector switch since power to various circuits including the compressor start circuit to start the compressor.

Controls, Heating and Cooling Units

Combination cooling heating units may be either plugged in appliances or through the wall.

Through the wall units usually have an electrical service furnished to the unit.

Typically a selector switch changes the unit from cooling to heating.

When the unit has a electric heat strip, the selector switch merely directs the power to the heating elements through thermostat.

If the unit is a heat pump it will have a selector switch to select heating or cooling.

Maintaining and servicing room units

Maintenance of a room units basically involves keeping the filters and coils clean.

The motor is typically a permanently lubricated motor.

If the filters are not maintained the indoor coil will become dirty and cause the unit to operate at low suction pressure.

While in cooling mode the coil is already operating in about 35°F. If the cold temperature drops any at all ice will begin to form.

Some manufacturers provide freeze protection that was shut the compressor off and often allow the indoor fan to run until threat a freezing is over.

This may be done with a thermostat located on the indoor coil or thermostat mounted on the suction line.

Service may involve electrical or mechanical problems.

Mechanical problems usually concerned fan motor and bearing or refrigeration circuit problems.

All room units have a critical refrigerant charge, and gauges should be installed only after some proof that the are needed.

The system will normally be sealed require line valves or the installation of a service ports on the process to support gauges to be installed.