Checking the AMP Draw of electric motors is important in HVAC for troubleshooting or testing a potential problem.

Furnace blower motors and condensing fan motors Amp draw are checked to see if they are Over-Amping or, in some cases, Under-Amping.

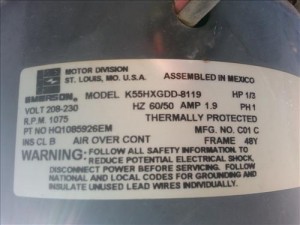

Every electric motor has a set Amp and voltage rating that the motor should run at. This information will be listed on a name tag on the motor.

The voltage can be 120 volts, 240 volts, and 460 volts; Amps can range from .01 to 20 amps or more.

Example condensing fan motor 230 volts 1.9 Amps.

Amperage is a measure of power being consumed by an electrical device. Furnace blower motors and condensing fan motors will have the Amps labeled on a name tag on the motor.

It can be labeled Amp, or in some cases, FLA (Full Load Amps), which is the max the motor is rated to run at.

When a motor Over-Amps, it is drawing more current than it was designed for, which will shorten its life and burn the motor up.

For example, if a condensing fan motor is rated at 3-Amps and after measuring the Amps, it is using 5-Amps, you know there is a problem, and it needs to be fixed before the motor burns up.

An electric motor will get very hot when it is over Amping; possible causes are the Start Run capacitors.

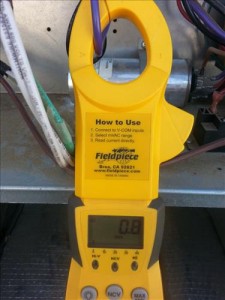

Use the Correct Multi-Meter with an Amp Clamp

A correct multimeter needs to be used when measuring amps so as not to burn up the meter.

Many HVAC multimeters are specifically designed and often use what are called Amp-Clamps, where a clamp is simply clamped around one of the wires the motor is pulling power from, and it will display Amps.

Multimeters that don’t have what is called an Amp-Clamp which use the leads from the meter set in the circuit to measure Amps.

Be sure your meter is set up to handle the voltage and Amps required before doing this, or it is possible to burn up your meter and possibly be shocked.

How To Measure the Amps an HVAC Motor Is Pulling

Take caution when measuring Amps or Voltage as HVAC has high voltage running to units. Also, be aware of moving parts such as the fan blades.

If you have a meter with an Amp Clamp, it will simply need to be clamped around a wire that is pulling power, which are the wires coming off the motor and going to the pole, 120 volts, 220 volts.

Only one wire is used to measure the Amps while the motor is running.

If you don’t have an AMP clamp but do have a meter that can handle the voltage and the Amps the motor is pulling it will need to be placed into the circuit.

For example, you have a 120 Volt 2-Amp furnace blower motor and need to measure the Amps. One of the wires for the 120 volts will need to be pulled out and placed on one lead. The other lead will go where the wire was pulled from, putting the meter in the circuit.

my technician says the following and suggests replacing the ten year old unit. What is your thought?-

Checked amperage on motors and compressor also checked electrical components and wire connections. System operating normal at this time maintenance complete

**Found both evap coil completely rusted out which may cause future leak in system, also found condenser coils at beginning stages of corrosion,

Recommend replacing both systems soon due to age and condition to prevent any further issues with system

Also found condenser fan motor on its way out to system #B (master unit) motor pulling .39 amps manufactures call at .75 amp if homeowner does not go with replacement recommend replacing motor to prevent no cool

Good work

Hi can you tell me why an inducer fan rated at 1.8 amps drops to 0.56 amps as soon as the main blower kicks in and therefore furnace flames are extinguished because of low pressure.

Main burners work fine and inducer draws 1.8 amps until main blower turns on.

Is this a problem with the board relays?