With so many HVAC Vacuum Pumps to choose from, how can you make sure you’re purchasing the right one for your job?

Main Things to Look for When Buying an HVAC Vacuum Pump

- CFM (Cubic Feet a Minute)

- Stage (1-Stage or 2-Stage)

CFM

The CFM (Cubic Feet per Minute) on HVAC vacuum pumps is how fast it can pump out air and can vary between 2-10 CFM.

5-CFM is good for small to medium-sized residential HVAC units.

For large 10-15 ton units, it would be better to have 8 or 10-CFM pump.

A 5-CFM vacuum pump will work at pulling down a large 10-15 ton unit but will be much slower.

HVAC Vacuum Pumps Stages (1-Stage vs. 2-Stage)

HVAC Vacuum pumps can be bought in 1-stage or 2-stage units.

1-stage units do not pull a vacuum as well as 2-stage units and are not as widely used anymore.

Single stage pumps would be good as a backup unit, a DIY individual, or for a part-time HVAC tech.

2-stage vacuum pumps can pull a much deeper vacuum and are the most widely used pumps.

They also work quicker pulling a vacuum which saves time and money.

One or two-stage units will both pull a vacuum with most professionals will use a 2-stage unit.

Below are our picks for the best HVAC pumps with links to Amazon to read the reviews yourself.

As always, be sure to read the reviews on Amazon, forums, or elsewhere to be sure a unit is a good fit for you.

*This post contains affiliate links

Our Picks for Best HVAC Vacuum Pumps

- ZENY 3.5 CFM Single-Stage (DIY Individual)

- FJC 6912 (Professional)

- Robinair 15800 (Professional)

- Yellow Jacket 93600 (Professional)

- JB Industries DV-200N (Professional)

It is a good backup or loaner unit and nice to have around if someone asks to borrow a pump.

While it can work in a professional environment, it likely won’t last long and need another unit in 1-2 years.

It is also a single-stage unit which means it cant pull a very deep vacuum and will take longer to pump a system down.

Still, its low cost makes it a good pump for someone looking for a budget unit.

FJC makes this 5.0 CFM unit that combines affordability with a good unit.

It is quieter than other units, although it can be a bit slower than comparable models.

The reason it is slower is it is a single-stage unit which is not the best for a professional.

While there are faster and more durable units that are built to last many years of daily use, the FJC is a good starter unit, backup, or the occasional HVAC tech.

Robinair makes many good units, including this 8 CFM model.

8 CFM may be overkill if you only work residential, but it is still a nice solid pump.

It is a 2-stage unit which means it can pull a deep vacuum with no problems.

This is a good unit for a professional HVAC tech and built to stand up to the daily use a pump will go through.

Yellow Jacket is another known manufacturer of vacuum pumps with many good units to choose from.

It is a Two-Stage unit that is a great little vacuum pump for HVAC work.

For the money, this unit may be one of the best HVAC pumps available.

It is built for professional use and will stand up to daily use for many years.

The cost is high, though, with cheaper units available for part-time users.

This pump from JB Industries is a high-end unit built for a professional HVAC tech.

It is a 7 CFM 2 stage pump that can pull 100 microns within roughly 15 minutes on a mini split.

High-end pumps are built for durability to last many years with good build quality.

Best HVAC Vacuum Pumps Comparison Chart

| Name | Stages | CFM | Voltage | Quality |

|---|---|---|---|---|

| ZENY | Single-Stage | 3.5-5.0 CFM | 115 V | Budget |

| FJC 6912 | Single-Stage | 5.0 CFM | 115 V | Mid-Range |

| Robinair 15800 | 2-Stage | 8 CFM | 115 V | Professional |

| Yellow Jacket 93600 | 2-Stage | 7 CFM | 115 V | Professional |

| JB Industries DV-200N | 2-Stage | 7 CFM | 115 V | Professional |

What are Vacuum Pumps Used for In Refrigeration HVAC?

Vacuum pump are used to place a HVAC system in a vacuum and remove contaminants.

In the early days of HVAC, vacuum pumps were not used. When fixing a system it was opened up and refrigerant was simply purged out. This of course that meant that moisture and assorted other non-condensable gases were let in.

A system in the early days had refrigerant dumped in one side and was purged out the other side.

This was done until the tech felt the system had gotten rid of all the non-condensibles and the system was mainly full of the refrigerant.

The problem with that was it was not complete and it didn’t pull out all the non-condensibles contaminants.

A non-condensibles is anything that will not participate in the refrigeration cycle.

These early systems had contaminants in the cycle and as they work through the system they just kept going through-and-through, they would cause corrosion.

All refrigeration system has oil breakdown even rust inside. An idea was introduced that a system should only have refrigerant and oil in the system.

To do this a refrigeration system needs to be placed in a Vacuum.

HVAC vacuum pump differ from regular pumps since they can pull a very deep vacuum.

In HVAC a vacuum is anything below zero psi.

You can never get all the way down to a perfect 30-inch mercury vacuum but you can get close with a good Vacuum pump.

Vacuum pumps made a considerable difference in the longevity of equipment and efficiency of equipment.

The one thing about vacuum pumps is they have to pull a very very low vacuum.

A good vacuum pump should be able to bring down an HVAC system to around 500 microns.

That is a complete system with oil and everything in it.

Remember you boil a little bit of the oil when you get way down into a vacuum it’ll boil something because as with anything the lower the pressure the lower the boiling point.

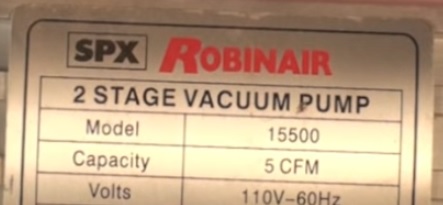

For example, here is a standard old pump that is a two-stage vacuum pump.

The motor is located at the back of the unit and pump at the front.

Two-stage vacuum pump has two separate pump points and are the most commonly used pump in HVAC.

Any HVAC tech today will use a 2-stage vacuum pump as they pull the deepest vacuum.

One-stage units are also still used but are not as common anymore since they cant pull as deep a vacuum as 2-stage pumps.

A 2-stage pump can also pull a vacuum quicker saving time and make a job quicker and easier.

Parts and Components of an HVAC Vacuum Pump

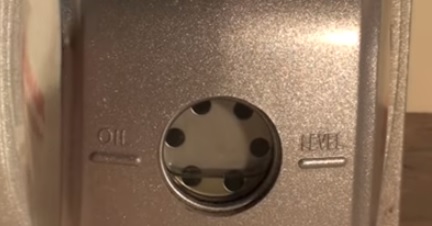

Oil Level Window

The oil level window will show how much oil is in the pump.

It will have a mark that should be watched and maintained as to not get too low.

Vacuum pump uses a special oil so be sure not to use any other type of oil such as motor oil or the pump will burn up.

The oil should be changed after every evacuation or it loses its ability to pull a deep vacuum.

Oil Drain Plug

The oil drain plug is usually located at the bottom of a pump.

It is there to make it easy to quickly replace the old oil with new oil.

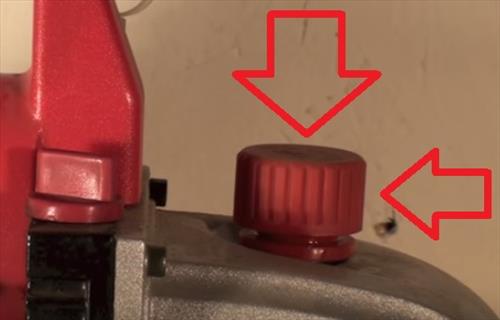

Oil Refill Cap

The oil refill cap is usually located at the top of a pump and makes it easy to add in new oil.

Most refill caps simply pull off and oil is poured in.

Discharge

The discharge is at the top be sure not to block it off.

Inlet Tap

There are two inlet taps located on the pump to hook up gauges.

The bottom one is 1/4 inch that fits with your gauge set.

The top one is 3/8 so if you have a 3/8 vacuum line which a lot of gauge sets do you can use it.

The idea behind having a larger vacuum line is because when dealing with small pressures it’s better to have a larger line to reduce pressure drop.

Sometimes accessories are added to the inlet such as a shut-off valve.

Personally, I do not prefer accessories as I’ve had a lot of them leak. There was certainly more service problems. I would just as soon have one that had no shut-off valve.

More Information on HVAC Vacuum Pumps

Most air conditioning systems today require a critical charge for optimal operation this makes them very sensitive to moisture and other contaminants which can freeze up the system, corrode the metals, and sludge the oil.

It’s extremely important to remove moisture with a quality vacuum pump before the critical charge takes place.

The contaminants from the system being evacuated can end up back-in the vacuum pump oil, so it’s necessary to frequently change your vacuum pump oil for peak pump performance.

You know why you need a vacuum pump but what size do you need for the job you perform on a regular basis?

Pumps are rated in CFM or how many Cubic Feet of air they move from the system per minute.

The faster air moves the faster you’ll reach the vacuum specified by the system manufacturer.

A general rule is to take the Square Root of the tonnage the system your servicing to determine the CFM rating you need for that particular system.

For example 16 to 25 ton systems typical for a residential air conditioning system would evacuate officially with a 4 or 5 CFM pump.

For large 36-264 ton systems which are found on most rooftops of large commercial buildings a 6 or 8 CFM pump would be ideal and so on.

Do You Really Need a Large Vacuum Pump for Small Jobs?

Well consider this, an 8 CFM pump will get you to 1000 microns more quickly then a 4 CFM Pump.

But once you reach 1000 microns all parts will work at approximately the same speed regardless the CFM rating.

On the flip side we don’t recommend using too small of a pump on a large system, as that will most likely result in premature wear of your pump.

Summary

When picking the best equipment for most anything opinions will vary and the above is simply from our experience.

For example, if you work mainly in commercial your requirements will be much different compared to a residential tech.

Other considerations to take into account when selecting a vacuum pump include a large oil fill opening which will make oil changes a lot faster and

easier.

A gas ballast feature which allows atmospheric air to enter the pump and mix with the exhaust gas. Preventing moisture from condensing in the pump oil

and keeping oil cleaner longer on system evacuations.

A built-in vacuum indicator to let you see exactly when it’s time to start using a micron gauge, and an isolation valve that allows you to isolate the pump from the system without losing the vacuum.

Finally make sure the pump you select has a stable base and isn’t too heavy for easy portability.