Using a vacuum pump to pump down a mini split line set is possibly the most troublesome part of DIY mini split installations.

Many new installers have issues with using a vacuum pump and HVAC gauges to set the system in a vacuum.

While the process is not difficult and the method I recommend using when installing an HVAC system, there are alternatives.

The two main alternatives are Quick Connect mini split units and using a KWIK-E-VAC line set flushing kit.

Quick connect units come with a sealed line set with the seal broken when bolted to the outside condenser.

Quick connect mini split work well but cost more compared to standard units.

The low-cost alternative to this is the KWIK-E-VAC flushing kit.

What is KWIK-E-VAC Line Set Flushing Kit?

The KWIK-E-VAC is meant to replace using a vacuum pump when installing a mini split.

The usual process when installing a mini split, is to vacuum down the copper lines set, and test for any leaks.

After the line set is in a vacuum and there are no leaks, the refrigerant is let into the system.

The KWIK-E-VAC is an alternative to pumping down a system by adding in a flush that blows out the line set and pressurizes it.

Once the line set is blown out, and the can pressurize the system, it can be tested with soap and water at the connections for any leaks.

It also is an alternative to Quick Connect type mini split units that have a sealed line set, that is only broken when bolted together.

Why Does a Mini Split Line Set Need a Vacuum?

The main objective of a vacuum is to test for leaks and get the line set free from any air or moisture that may damage the system.

The goal is to get rid of anything that shouldn’t be there, such as moisture, solid contaminants, and other refrigerants, including oxygen.

These things are called non-condensable since they do not condense as the refrigerant does and can cause damage to the system.

Non-condensable is a term often used for anything that does not belong in the system.

For example, water particles are non-condensable that corrode the system and cause damage if not removed.

During a vacuum, moisture begins to boil away and is removed along with other non-condensables.

While a vacuum is the most common way to remove non-condensables other methods can also be used.

Should You Use KWIK-E-VAC Line Set Flushing Kit?

When done properly, using the KWIK-E-VAC system will work and is a low-cost way to install a mini split.

Personally, I will always use a vacuum pump and gauges since I have installed many units this way, and the process is simple, at least to me.

When working with HVAC installers, methods can defer with some techs having a preferred method they use and insist it is the only way to install a unit.

For example, many techs will pressurize the line set first with nitrogen to test for leaks and then pump it down with a vacuum pump.

This is a good method, but for me, if the system is leaking, it will not hold a vacuum, so personally, I don’t do the nitrogen test.

After many installations, I have never had any issues, but many installers I have worked with will still insist on a nitrogen test.

I have no issues with a nitrogen test; if they want to do it, go for it; this is simply an example of how methods can defer.

Whether you should use the KWIK-E-VAC or a vacuum pump is a personal choice for the method you feel best using.

I would always suggest using a vacuum pump, but this is my personal choice.

KWIK-E-VAC Line Set Flushing Kit Available Here on Amazon

Pioneer KWIK-E-VAC Line Set Flushing Kit Installation Simplifier for Mini Split Air Conditioning Systems

The below is a basic overview of using the KWIK-E-VAC Flushing Kit. Be sure to always follow the instructions that come with the kit.

Steps To Use KWIK-E-VAC Line Set Flushing Kit

- Turn of any power going to the unit.

- Keep the can upright at all times when flushing the system.

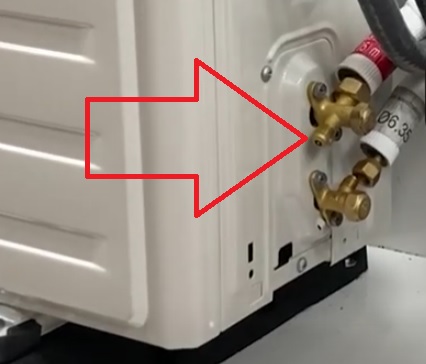

- Tighten all the line set connections except the high pressure side (small line) at the outside condenser.

- Attach the hose to the can.

- Remove the cap to the service port on the low pressure line (Big line).

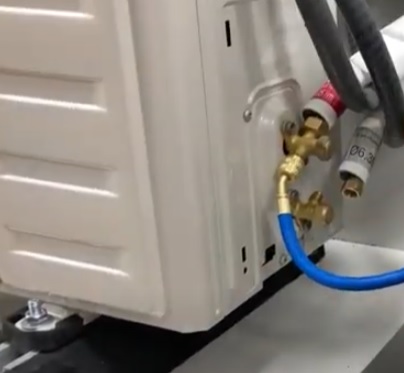

- Attach the hose to the service port on the low pressure line (Big line).

- Open the can valve to begin flushing.

- The gas will be heard coming out the open high pressure line.

- After roughly half the can is gone, quickly close the line, set the low pressure side, and tighten it to specification.

- Listen for any leaks both inside and outside and test the connections with soapy water for any leaks.

- Once the system is tested for leaks, unscrew the line to the can to let out the gas.

how do I know if 1/2 the3 can is gone?